PowerCalc(tm) easily saves over 40% in design time.

In this 3rd newsletter of our series, the need for faster design response for increasingly complex buildings and equipment continues. In the 1st article, the multiple ways that PowerCalc(tm) meets this need for speed was discussed: automated calculations instead of manual, one integrated and bundled calculation, automatic / simultaneous 1 Line Diagram, and more. Need for Speed

Next, PowerCalc's patented approach to automation was reviewed: calculations, NEC compliance and integration.No Problems / Only Solutions

In this article, PowerCalc's equipment schedules and cloning function show how design time is reduced even further.

1. Equipment Schedules

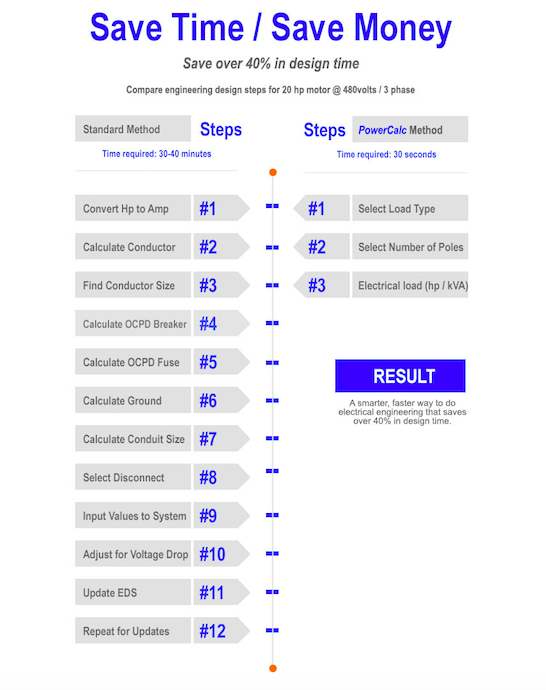

Each piece of equipment has its own schedule. The table above outlines PowerCalc's process for a 20 HP motor at 480 volts/3 phase.

With just 3 inputs, all electrical characteristics/requirements for each piece of equipment is calculated taking a few minutes at most. In contrast, the typical way of doing these calculations takes about 45 minutes. Again, just this improved process alone illustrates that PowerCalc saves at least 40% in total design time.

And even more time is saved due to the equipment schedules tracking all the characteristics and electrical requirements for each piece of equipment, even the most sophisticated in a single location due to the software's interoperability, i.e. integration.

PowerCalc's interoperability is more than simple data transfer. Instead PowerCalc provides for the exchange of information enabling the instantaneous and simultaneous performance of load and fault current calculations, voltage drop and even updates for the 1 Line Diagram. The inputs for the equipment instantaneously populate the entire design - upstream and downstream.

Can't get much better than this process in terms of the quality, usefulness and speed of your design and process.

2. Cloning

Design one floor and you've designed them all. This function really speeds up the design of high rise buildings, multiples of the same building such as greenhouses, etc. Works for any facility with multiples.

So, if you are tired of a tedious repetitive process of duplicating floors,etc., realize that such a process is unnecessary. Today, why would any electrical professional not demand that one floor's design be cloned for all 50 floors?

All of PowerCalc's functions move the electrical professional to faster design with more accurate results, fewer lawsuits, change orders and building department comments. Couple all of these benefits with the acceleration of the PowerCalc process, and at least 40% is saved in design time.