Traditional and current electrical design practices for Voltage Drop overlook best practices relevant for digital age facilities such as data centers, robotic manufacturing complexes, and more. It is time to re-think current practice to capture extreme savings in both energy use (at least 7%) and electrical equipment (over-specification of equipment -- too much expensive copper).

Read More >Voltage Drop in Data Centers: Re-think for Extreme Savings in Energy

Shark Bait: 7%+ in Energy Savings

|

|

Click to watch: Shark Bait: 7%+ in Energy Savings Watch to see how PowerCalc applies known science to save 7%+ of electrical energy use. At the NetZero Accelerator of the US Green Building Council's LA Chapter, PowerCalc presented all the details to a shiver of sharks in a feeding frenzy. Watch the video to see the action for yourself. Hi, I’m June Adams, CEO of PowerCalc. Let’s talk about saving at least 7% of electrical energy use in each circuit, each building, and each city. A dramatic proposition. There are 2 electrical delivery systems…one is the power grid and the other is the electrical distribution system inside the building. The conductor is the single longest link between where electricity is generated and where it is used…but no one is talking about it. Why? Because designing the electrical distribution system is complicated…about 2000 calculations for a 10,000 SFoffice building. PowerCalc is patented software that automates these calculations. It designs differently adding actual electrical demand loads from the circuit to the grid’s entrance to the building or bottom-up. In contrast, our competitors, design from the top-down basing their calculations on estimates. Simply, PowerCalc’s 7.5 M integrated equations let lots of great things happen—exacting accuracy, fast design, easy, and green. And, for the first time, the detail of specifying conductor sizes is easily possible resulting in incredible savings in electrical energy use, electrical equipment / copper, and SF of space. All of this is based on established science. In 1827, Ohm’s law identified the measurement for the electron’s difficulty in passing through material. If there is resistance, heat is produced indicating energy losses. But correctly sizing conductors reduces this resistance and also reduces heat and energy loss. It is time to implement established science for energy savings of at least 7% with PowerCalc. That’s close to $17 per 20 Amp circuit per year. And, that’s enough energy to run a water heater for 7 days. What about materials and space? A recent backup generator installation called for (10) 112 kVA transformers. In a peer review, PowerCalc re-specified this equipment downsizing to (10) 30-45 kVA transformers for over $2 million in savings in a third of the SF of space. ROI is about 2 years, also calculated by PowerCalc. Simply, it is time to implement established science for energy savings of at least 7% with PowerCalc. Last, PowerCalc is well recognized. We’ve included information on our great team as well as a few case studies for your review. Thank you, and it would be great to speak with interested parties about possible investments and pilot projects. |

|

| And remember, we have a free live / real time demonstration on the first Friday of each month: FREE Demo, Friday, June 4th at 12 pm EST . And here is a video of a recent demo Video of PowerCalc Demonstration Hope you will join us! Thank you for your support! Stay well. |

Case #3: Better Estimates for Electrical Costs

|

Case #2: South Florida Country Club Saves $2,000,000

|

In a peer study,

PowerCalc was used to review the installation of a backup generator.

The electrical design for the installation specified ten (10) 112.5 kVA transformers. That's a lot of transformers, an oversight easily identified by a seasoned professional. This specification is about three times (3X) the amount of electrical power typically designed for such a facility (10W / SF instead of 3 W / SF).

Running the same design through

PowerCalc resulted in a reduction of this specification for transformers instead to ten (10) 30 kVA to 45 kVA transformers. This "downsizing" resulted in over $2,000,000 in savings by not only reducing the size of the transformers, but also the related conductors and conduits.

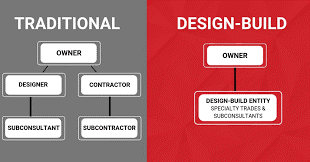

For all involved in construction every day, these types of mistakes are not uncommon. These issues arise from the current electrical design practice of using "rules of thumb", makeshift spreadsheets, and software that "designs" from the

top-down

(

estimating

the total electrical load at the start of design). The accurate design approach is to instead know the

actual

electrical demand load by adding electrical loads from the circuit to the facility's connection to the power grid (

bottom-up). This

bottom-up

approach is

PowerCalc's patented design methodology.

In contasting approaches,

guestimating

the size of the electrical load in conjunction with pre-sets for panelboard sizes, transformers, equipment disconnects, feeders, and overcurrent protection devices at the start of the project may lead to an

inaccurate

baseline on which to build the electrical engineering design instead of an

accurate calculation of the

Total Electrical Load

based on the project's

actual

electrical demand.

This distinction in approach is important as electrical equipment that is (1)

oversized

results in increased costs for the developer and/or owner for expensive electrical equipment as well as wasted electrical energy and (2)

undersized

results in a potentially increased risk to safety (fires).

FYI: the initial design was done by an engineering consulting firm ranked in the top 100 nationally using leading electrical design software with a top-down design approach.

*********************************************************************************************************

Join us for a Free Demo of

PowerCalc - the 1st automatic electrical engineering design software in the cloud for compliance with the NEC and with simultaneously generated 1 Line Diagram!

When: Friday, April 9 at 12:00 PM Eastern Time (US and Canada)

Sign Up:

A

fter sign up, you will receive a confirmation email containing information about joining the meeting. You can also see our most recent demonstration on video: PowerCalc Demo: July 10, 2020

Our software is a fully integrated design application that saves you time and money. This is PowerCalc...an incredibly powerful tool that's unexpectedly easy to use for compliance with the NEC. |

|

Case 1: Broward County Schools - "Rightsizing" in Renovation

|

It is a big deal: over 200 schools in the Broward County School District (BCSD) are currently being renovated. Per

Wikipedia: BCSD is the 6th largest school district in the country and 2nd largest in Florida with over 271,500 students and 327 schools and education centers.

Eighteen (18) of these 200 schools were designed using

PowerCalc(tm).

It provided a material "value add" for these renovations with savings for BCSD as described below.

Using

PowerCalc,

existing conditions were documented. Recognizing that not all renovations are a total demolition,

PowerCalc did the new design based on documented existing conditions to "rightsize" and locate the electrical equipment. Take a look at

PowerCalc's automatically and simultaneously generated 1 Line diagram for more on how this works:

Incredible 1 Line Diagram

PowerCalc identified and corrected existing design issues with its approach. Here are a few examples:

1. An initial design for replacement of a new air handling unit specified installation of an additional electrical panel located at some distance across the facility Instead,

PowerCalc identified an existing electrical panel located next to the air handling unit to energize it at a fraction of the cost.

2. Another school called for replacement of the entire electrical distribution system. Rather than replacing equipment with the same sized equipment,

PowerCalc's design replaced the existing equipment with smaller sized equipment that occupied less space and allowed for re-use of the same electrical room.

In both of these situations, major expenditures were avoided in terms of the cost of new equipment such as electrical panels, conductors, and transformers while also saving installation costs and building modifications. A higher quality design was provided by

PowerCalc with a 40% reduction in design time.

PowerCalc identified oversizing and undersizing issues with feeders and branch circuits, related overcurrent protection devices (circuit breakers and fuses) as well as excessive voltage drop.

*********************************************************************************************************

Join us for a Free Demo of

PowerCalc - the 1st automatic electrical engineering design software in the cloud for compliance with the NEC and with simultaneously generated 1 Line Diagram!

When: Friday, April 2 at 12:00 PM Eastern Time (US and Canada)

Sign Up:

A

fter sign up, you will receive a confirmation email containing information about joining the meeting. You can also see our most recent demonstration on video: PowerCalc Demo: July 10, 2020

Our software is a fully integrated design application that saves you time and money. This is PowerCalc...an incredibly powerful tool that's unexpectedly easy to use for compliance with the NEC. |

|

The Happiest of Holidays to You!

2020 Annual Conference of Florida Engineering Society

When: Tuesday, September 8, 2020 from 2:00pm – 3:00pm.

Course Description: "The idea is novel... no Code I am aware of addresses optimization of electric delivery and distribution systems...before a building is complete." Grant Reviewer, US DOE. Whether the power grid or a building's power distribution system, the conductors/wires that transmit electricity are the single largest link between the generation and end-use consumption of electricity. We will examine the math in engineering equations and several buildings.

Speakers: Mr. James Khalil, PE and Ms. June Adams, JD

Biography: June Adams, JD: Passionate leader of technology startup. Strategic thinker with over 20 years of experience as an attorney and executive in major corporations. Co-founder of a company whose vision is excellence in engineering with the goal to design power distribution systems to function optimally in buildings, college campuses and industrial facilities.

James Khalil, P.E. is President and Inventor of PowerCalc. He has 30+ years of experience at Florida International Consulting Engineers, his MEP firm in Delray Beach, FL, and Carter Burgess (now Jacobs) in Fort Worth, TX; Mason & Hanger in Lexington, KY; and Gee & Jenson (now CH2M) in West Palm Beach, FL. He received his B.S. Electrical Engineering from the University of Texas. His experience includes projects for Saudi Arabia and Dubai.

You can register for this event by clicking on the hyperlink below:

Event Registration: Commit to Green: The Conductor is the Link to Save at least 7% of Electrical Energy Use

Pricing:

| FES/ACEC-FL Member Price |

Non-Member Price |

| $35 each or $25 each as a package ($200 total) |

$70 each or $60 each as a package ($480 total) |

*You must be logged in to your member profile to receive the member price

And remember, we have a free live / real time demonstration on the first Friday of each month: FREE Demo, Friday, Sept. 11th at 12 pm EST And here is a video of a recent demo https://www.youtube.com/watch?v=gDQgCOu2_LA Hope you will join us!

Thank you for your support! Stay well.

Circuit-by-Circuit, Building-by-Building, City-by-City

PowerCalc is an exhibitor in the Municipal Green Building Conference and Expo on August 21 and 22nd in Los Angeles as a participant in the 2020 Net Zero Accelerator of the US Green Building Council's LA

Since its inception in 2001, MGBCE has become the longest-running and largest gathering of leading sustainability and green building advocates within both the public and private sectors of Southern California. Over 1,000 attendees are expected on August 21st and 22nd in a virtual setting from local government agencies, the building industry, and the public, all gathering to learn about green building principles, practices, and products.

The focus is best in class content featuring live streaming, interactive exhibitor, and community partner booths, virtual tours, digital networking, recorded content, and much more.

PowerCalc's introductory video is attached. And, here is the text of our statement:

After 100 years, it is time to change from the waste of Thomas Edison’s day to the efficient use of electricity, copper, and space.

So, out with the old and in the new and that’s PowerCalc. It is patented software that automates the design of the electrical distribution system inside the facility for extreme savings before a building is even built or renovated. All in compliance with the National Electrical Code for the Building, Construction and Facility Management Industries.

But let’s start at the beginning. Electricity powers virtually everything in our world. It is delivered through 2 systems: the power grid outside the building and then inside from the power grid’s connection to the circuit (the light switch or outlet).

Designing the building’s system is complex and requires about 2000 calculations for a 10,000 SF office building. Also, current design practices need to change to save energy. For instance, data centers are gluttons using 3% of global electricity.

The solution is PowerCalc. PowerCalc designs from the bottom up -- that’s from the circuit to the connection to the power grid for design based on the actual electrical demand load. PowerCalc is exactingly accurate because its calculations are based on real numbers.

PowerCalc is also easy, fast, and very green. Easy with just 3 inputs per circuit saving at least 40% in design time, and also saving at least 7% in energy use.

In contrast, other electrical softwares design from the top-down with results based on estimates such as the size of the panel frame, feeder sizes, and on and on.

To compare these two approaches, PowerCalc did a peer review of a generator design at a country club. Instead of (10) 112 kVA transformers, PowerCalc reduced these sizes for over $2 million in savings in half the square footage of space.

PowerCalc focuses on the circuit as it is the delivery point for the distribution of electricity by the conductor. The conductor is the single largest link between where electricity is generated (whether at a power plant, solar panel or wind turbine) and where it is delivered and used (again, that light switch or outlet).

For the first time, calculating the exacting detail of conductor sizes is easily possible. Sizing conductors optimizes the delivery of electricity circuit-by-circuit reducing energy losses.

This results because electricity is not hot but becomes hot when electrons are squeezed through a conductor / wire without a clear path. A larger conductor allows electrons to travel without bumps reducing friction and energy loss.

Remarkably, by increasing the conductor size the electrical load on that conductor can be doubled and also reduce the number of circuits required to save copper.

In summary, PowerCalc results in extreme savings in both the use of electrical energy and equipment as well as SF of space.

PowerCalc calculates both energy savings and return-on investment at the preconstruction / design stage of a project.

PowerCalc was Product of the Year for Consulting Specifying Engineer, in 2016 and 2019.

And remember, we have a free live / real time demonstration on the first Friday of each month: FREE Demo, Friday, Sept. 11th at 12 pm EST And here is a video of a recent demo https://www.youtube.com/watch?v=gDQgCOu2_LA Hope you will join us!

Thank you for your support! Stay well.

NetZero Accelerates the Way to Green

LOS ANGELES (July 16, 2020) The U.S. Green Building Council-Los Angeles Chapter (USGBC-LA) is excited to announce the second cohort of its Net Zero Accelerator (NZA), a major chapter initiative that identifies viable net zero building solutions, positions them for success, and accelerates their market entry throughout the greater Los Angeles region. The 17 member companies have been selected for their strong potential to be game changers in building technologies and materials as well as jobs creation, and with solutions ranging from reducing carbon across emissions-intensive industries to saving buildings from wildfires to providing access to clean power anytime and anywhere.

The first accelerator of its kind to help achieve net zero goals, the USGBC-LA’s cohort addresses:

- Advanced Materials – CO2 Concrete, DryWired, ePAVE, Mi Terro, Rizome, SierraCrete, TBM Designs, U-STUCCO

- Building Systems – Frontline Wildfire Defense, Point Load Power, Rivieh, Teratonix

- Energy Efficiency – Maalka, PowerCalc

- Energy Storage – ONYX

- HVAC Optimization – WeavAir

- Sustainable Landscaping – Robotic Lawn Care Systems

(Full list and descriptions attached at end, or click here.)

The companies will be on display and able to interact with attendees at USGBC-LA’s virtual Municipal Green Building Conference & Expo (MGBCE), Aug. 21-22. To attend, please click here.

The companies will be on display and able to interact with attendees at USGBC-LA’s virtual Municipal Green Building Conference & Expo (MGBCE), Aug. 21-22. To attend, please click here.

“This is an exceptionally compelling group of companies commercializing and scaling diverse solutions that address our shared goals. We're excited to help them overcome market-entry barriers often encountered by new technologies. A big part of achieving this is in how we pair them with green building experts and significant pilot sites throughout our region to increase their momentum and quickly see results, optimally before the new year,” states Colin Mangham, newly appointed Director of the Accelerator.

Mangham has guided the success of dozens of global brands as well as hundreds of entrepreneurs, and has headed marketing for seven early-stage companies, several times as Chief Marketing Officer. He consults internationally on brand positioning and go-to-market for startups and growth-stage ventures, as well as speaks and lectures on social entrepreneurship and bioinspired innovation. He was recently featured on CNN as the Founder of Biomimicry LA, and served as the CMO of Biomimicry 3.8 and the Biomimicry Institute, for which he has helped grow the Global Design Challenge.

The 17 companies were selected from 161 applicants (double that of 2019), reflecting the high quality of submissions, the significant interest in piloting a technology in one of the most progressive net zero regions in the world, and the breadth of partners engaged in the Accelerator. The cohort members hail from the Los Angeles/Orange County regions and Northern California, Florida, Hawaii, New York, and Wyoming.

The 2019 cohort's 13 technologies are currently making their way into the marketplace with 30 pilot projects being tracked by USGBC-LA, including Keewi at Kilroy Realty Corp., and Blue Box at CA State University at Dominguez Hills.

Stated Jose Urizar, founder of 2019 cohort member DTE Materials, “The NZA was a great opportunity to be matched with industry and product specific mentors that are keen to the nuances that startups in the built environment experience. The USGBC-LA ecosystem and network were very helpful and welcoming to our team, and we recommend this opportunity to building technology and materials startups in the Southern California region.”

The following expert building owners/operators, industry experts, investors, utilities, and large corporates have committed their engagement to help get the 2020 pilot-ready technologies into buildings: All About Waste, Blue Bear Capital, BuroHappold Engineering, CA State University at Dominguez Hills, the City of Los Angeles, Community Corporation of Santa Monica, Fifth Wall Ventures, Frederick Fisher and Partners, Gensler, HDR, Hudson Pacific Properties, i(x) investments, Integral Group, Kilroy Realty Corporation, the Los Angeles Department of Convention and Tourism Development, the Los Angeles Department of Water and Power, the Los Angeles County Economic Development Corporation, NRDC, Passive House, Rising Realty, Skanska, Southern California Edison, Southern California Gas Company, UCLA, The Westin Bonaventure, Unibail-Rodamco-Westfield, and Vanir Construction Management, Inc.

The Net Zero Accelerator was conceived by USGBC-LA Executive Director, Ben Stapleton, with a focus on addressing market barriers for increasing the sustainability of buildings throughout the region. He believes the Accelerator is a key component to building a regional innovation hub and sourcing pilot-ready solutions that help the region get to zero carbon, zero energy, zero water, and zero waste, emphasizing promotion and placement of pilots with building partners at the end of the program.

“We're incredibly excited to build upon the success of the 2019 program, expand our innovation ecosystem in the real estate community here in LA, and ultimately help get technology to market that can have positive impacts on the environment around us,” states Stapleton. “Operators of building types of all kinds across the City have raised their hands to provide pilot sites and their expertise to help us get to net zero, with increased focus on resilience, clean construction, and occupant health. Our goal is to work with our advisors to fine tune the technical and business models of these technologies, helping to deliver solutions today in a way that they can scale at an accelerated rate going forward.”

With no equity participation required, the six (6)-month Accelerator runs through December 31st and includes:

High-impact acceleration services with industry experts, focused on results.

Sustained, professional marketing and storytelling through a leading and respected organization to amplify awareness of cohort companies and technologies.

High potential for pilots with partner building sites, with leads and business development opportunities from committed owner-operators.

Peer-to-peer learning, networking, and talent sourcing opportunities.

For more information on the Net Zero Accelerator, contact Colin Mangham at accelerator@usgbc-la.org. For information on USGBC-LA, please contact Ben Stapleton at ben@usgbc-la.org.

------

About U.S. Green Building Council-Los Angeles

USGBC-LA is a 501(c)3 nonprofit organization committed to creating a prosperous and sustainable future within one generation. Our mission promotes sustainability in LA County's built environment by delivering access to knowledge, resources, recognition and networking. (www.usgbc-la.org)For more information on the Net Zero Accelerator, contact Colin Mangham at accelerator@usgbc-la.org. For information on USGBC-LA, please contact Ben Stapleton.

You can see our most recent demonstration on video: PowerCalc Demo: July 10,2020 And remember, we have a free live / real time demonstration on the first Friday of each month: FREE Demo, Friday, August 7th at 12 pm EST Hope you will join us!

Thank you for your support! Stay well.

Now Available! Video of PowerCalc Demo

In response to your requests, here is a link to the video of last Friday's demonstration of PowerCalc. There was a good turnout with lots of great questions. For those of you who were unable to attend, here is the link:PowerCalc Demo: July 10,2020

Just so you know, we are available for individual or group demonstrations in real time whenever convenient for you. Just let us know and we'll make it happen.

Also, upon request, we are available to demonstrate how to use PowerCalc for better design build estimates, to save energy, and more (like how our cloud system works for an enterprise). These applications were not demonstrated last week so are not included in the video shared today.

A Few Announcements:

- The US Green Building Council of Los Angeles has just named PowerCalc one of 17 companies participating in their NetZero Accelerator. We were selected out of 164 applications from around the world. More on the NetZero Accelerator in future newsletters. We look forward to sharing all that happens.

- Join us at the Florida Engineering Society's Annual Meeting on Tuesday, September 8th at 2 pm. Our topic: Commit to Green: the Conductor is the Link to Save at Least 7% in Electrical Energy Use. We will be expanding our discussion from the limited subject of the conductor to also include the electron's journey through the conductor. Like PowerCalc, the new field of spintronics in the electronics world, focuses on limiting energy lost due to the generation of heat when electrons are distributed through a wire.

- Just to continue PowerCalc's hectic pace, within the next 4 weeks we launch our industrial package: the first software to automatically design Automatic Transfer Switches, Motor Control Centers, Double Ended Switchgear, Unit Substations, and more. All will be indicated in PowerCalc's automatic and simultaneously generated 1 Line Diagram.

The industrial package joins our long list of "firsts":

(1) first electrical design software in the cloud (Product of the Year 2016, Consulting Specifying Engineer) (one and only) ;

(2) first to design from the circuit out to the service entrance (bottom-up) for calculations based on the actual demand and connected loads / never on estimates (exactingly accurate);

(3) first to have just 3 inputs per circuit for over 300 NEC compliant outputs (load kVA, # of poles, and load type) (incredibly easy);

(4) first to have automatic and simultaneously generated 1 Line Diagram (Product of the Year 2019, Consulting Specifying Engineer) (technology magic);

(5) first to save at least 40% in design time (very fast);

(6) first to have an energy module to save at least 7% in energy use (optimizing electric energy before a building is completed) (green innovation);

(7) first to use the US Army Corps of Engineer's panel format (best practices observed);

(8) first to mirror the NEC’s structure: branch circuits / conductors, equipment, and special occupancies (the automated NEC).

PowerCalc not only designs the power distribution system in a building, but can be used to maintain an inventory of electrical equipment and design for facility management.

And remember, we have a free live / real time demonstration on the first Friday of each month: FREE Demo, Friday, August 7th at 12 pm EST Hope you will join us!

Thank you for your support! Stay well.