Electrical Design goes Green

"The idea is novel, in that it adds an energy savings dimension past standard Codes for envelope, HVAC efficiencies, and LEED requirements. No Code I am aware of addresses optimization of electric delivery and distribution systems that can be quantified by a similar method. If successful, the electric design industry can add a powerful tool to electric energy optimization even before a building is completed."

What happened?

In our last two articles, we discussed our application to the US Department of Energy for a grant to incorporate PowerCalc's energy savings module into the Whole Building Energy Savings platform. This is a global initiative moving the earth forward to save energy in buildings addressing smart buildings and cities as well as net zero energy and carbon buildings. Our application was approved, but did not make the priority for funding based on the project's specific objectives (sensors, etc.) The above quote is from the DOE reviewer's assessment.

Prior articles: At Least 7% Energy Savings; Data Centers

How can PowerCalc save at least 7% in energy use?

Unlike other electrical design software, PowerCalc designs from the bottom-up, i.e. from the circuit to the service entrance / power grid inside a facility. For the first time, the ability to calculate and specify the exacting detail of conductor sizes is easily possible. No need to just use the same conductor size throughout the design. This added design feature can save at least 7% in energy use and very likely a lot more.

In this article, let's look at the numbers to assess PowerCalc's unique focus: on the conductor / wires that transmit electricity..the single largest link between the generation and end-use consumption of electricity. It is effective in designing any power distribution system in a facility with electricity generated from any power source (solar, wind, coal, etc.).

ERASE(tm)

PowerCalc's Energy Savings Module (ERASE) reduces energy lost during the transmission of electricity because electrons bump into other electrons and atoms. In other words, there is "friction". This "friction" is reduced when a larger conductor is used allowing more room for movement resulting in the reduction of heat generation / energy loss. ERASE(tm)

PowerCalc automatically calculates and re-calculates for changes and conductor sizes circuit-by-circuit to minimize energy loss and maximize energy savings. It also calculates the Return-on-Investment (ROI) to determine the economic costs and benefits of increasing these sizes. Significant savings are achieved by minimizing energy wasted through heat loss and maximizing energy saved.

The Calculations

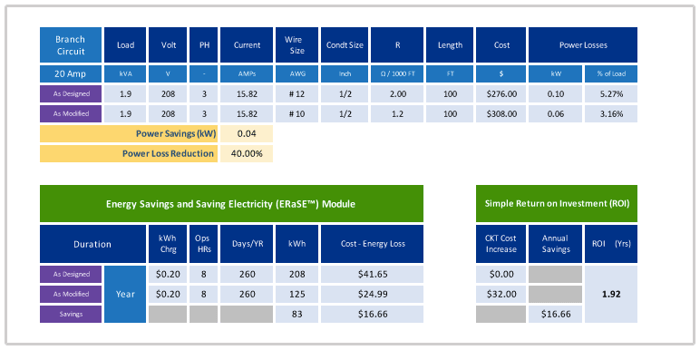

Assume the following: L = 100 ft., voltage 208Y / 120, 8 hours of operation at $0.20 per kWh. Note: You can adjust both hours of operation and cost of kWh to suit any project.

Per the NEC, the design of a typical 20 amp circuit with 1.9 kVA load requires #12 AWG Branch Circuit Conductors installed in 1/2" conduits. Applying the engineering equation below, 4.22% of the energy delivered to the load will be dissipated per 100 ft. of branch circuit conductor.

If the #12 AWG is modified to #10 AWG and installed in the same 1/2" conduit, then only 2.53% of the energy delivered to the load will be dissipated through the same 100 ft. of branch circuit conductor. This is a reduction in energy loss of approximately 40%. The Simple Return on Investment is 1.92 years per the calculation below.

Energy Losses = I2 x R

Where R is the conductor resistivity and I is the electrical current in amps.-

Design of Circuit without using ERASE

Energy Losses = 0.100 kW

Modified Energy Losses with ERASE

Energy Losses = 0.06 kW

Comparison = 0.04 kW saved with ERASE

Annual Energy Loss Cost "as designed" without ERASE = $41.62 per circuit

Annual Energy Loss Cost "modified" with ERASE = $24.97 per circuit

Annual savings "modified" with ERASE = $16.65 per circuit

The cost increase for #10 wire = $32.00 per circuit

Simple Return on Investment (ROI) = $32.00 / $16.65 in 1.92 years

Just these simple steps and PowerCalc automatically generates a power distribution system that saves energy and reduces the building's carbon footprint.

Is this commercially viable?

Return-on-Investment is at most 2 years for new construction and retrofits.

In new construction projects, resistivity is applied as part of the engineering process using PowerCalc's integrated system to design the power distribution system in a building.

In new construction projects, resisitivity is applied as part of the engineering process using PowerCalc's integrated system to design the power distribution system inside the facility.

And in retrofits, the process is easier than you think. Just re-calculate the feeders and branch circuits, and then pull new conductors / wires in existing conduits. There are no expensive energy audits and no significant design time. Design time for any project is likely reduced by at least 40% using PowerCalc.

Note: It is unlikely that new conduits are necessary as the NEC requires that conductor / wire fill not exceed 40% of the conduits' cross sectional area...and that is a lot of space. NEC Chapter 9 Table 1 "Percent of Cross Section of Conduit and Tubing for Conductors". But to make certain there is no issue, PowerCalc calculates the conduit size needed and directs it to be increased as necessary.

Listed on US DOE's Building Energy Software Tools Directory

PowerCalc is listed on the US Department of Energy's Building Energy Software Tools Directory.

What's next?

PowerCalc is applying for more grants. As part of this process, we are looking for partners to work with on relevant projects. If you'd like to work with us, it would be great to speak with you. See my contact information below.

Join us for lunch on Friday, September 6th, for a free demonstration of PowerCalc: software that automatically designs the power distribution system inside a facility and simultaneously generates the 1 Line Diagram.