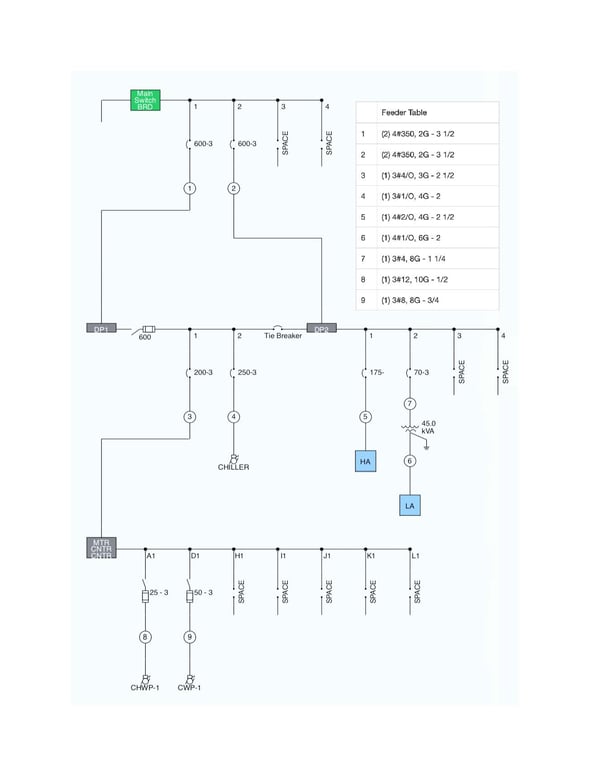

Fig 1: 1 Line Diagram: PowerCalc with Feeder Table

At PowerCalc, everything is focused on the electrical circuit. Our patented software starts at the circuit adding loads to reach the service entrance for exacting accuracy in our calculations and incredibly fast design of the power distribution system (PDS) inside a single or multiple facilities. The PowerCalc system mirrors the National Electrical Code's (NEC's) "bottom-up" framework and automates all the calculations required for compliance with the NEC.

But, in speaking with a user recently, the power of PowerCalc's 7.5 million equations took on a new use. What if PowerCalc's automatic calculations are used to estimate the size and characteristics of the electrical equipment and labor costs for the PDS in bidding Design Build projects.

In today's construction industry, a preferred method for construction is Design Build. The Design Build process combines the design of the structure with the construction cost in one price submitted to the owner. In order to bid, the Design Build contractor needs to determine what equipment is necessary and its costs prior to the PDS even being designed.

In a Design Build construction project, as opposed to a conventional method of design / bid / construction, the contractor is locked into its bid. Currently, the bid for a Design Build construction project is based on estimates often relying on "rule of thumb" electrical design. The reality is that the actual quantity and price of the electrical equipment for the power distribution system is likely not known at the time of bid

For sure, PowerCalc can help the Design Build contractor to accurately estimate the cost of providing the electrical equipment and labor for the project. The reason for using PowerCalc for such an estimate is that only PowerCalc can provide the details like sizes and quantities for the necessary equipment such as Main Distribution Panel, Distribution Panels, Lighting / Power Panels, Motor Control Centers (MCCs), Automatic Transfer Switches (ATSs), UPS Transformers,and Generators.

PowerCalc does not stop there, but also sizes and quantifies this equipment and associated conductors (with neutral and ground), conduits, overcurrent protection devices, panel frame / main, phase, equipment AIC ratings, and voltage drop. In short, estimates based on PowerCalc's calculations allow the design bid quote to be much closer to actual cost.

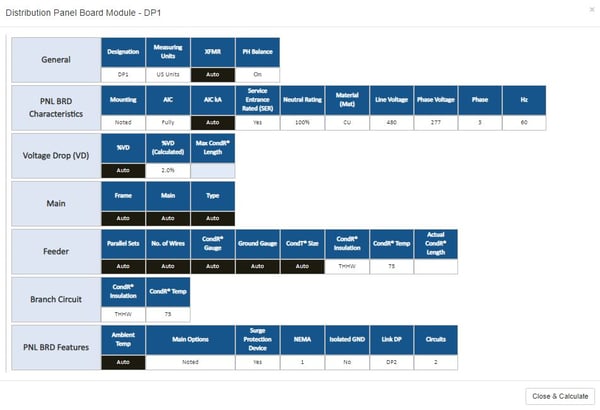

Fig 2: Settings on Panel WIZARD

So, let's step through the process of how to use PowerCalc to put together an electrical cost estimate for a Design Build project. At the Panel WIZARD, override the "Auto" pre-set functions and instead input estimates such as the panelboard "Main" size. With this single input, the results estimate specifications for feeder, conduit, ground, overcurrent protection devices, voltage drop, equipment AIC ratings, and fault current calculations. See Fig 2: Settings on Panel WIZARD

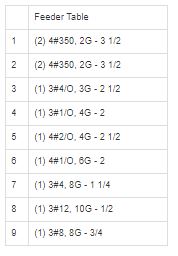

With this information, PowerCalc generates a basic layout of the PDS with its automatically and simultaneously generated 1 Line Diagram. See Fig 1: One Line Diagram Included with the 1 Line Diagram is the Feeder Table indicating the number and size of feeders conductors. See Fig. 1: 1 Line Diagram with Feeder Table and Fig 3: Feeder Table from 1 Line Diagram

Fig. 3 Feeder Table from 1 Line Diagram

Also useful for a Design Build estimate, is that any change is easy. Change an input anywhere...and all values on the PDS and 1 Line Diagram are instantaneously updated across the entire PDS both upstream and downstream.

This is a wealth of information for estimators to use for Design Build projects. While still estimates, the quantity and sizing of necessary equipment is much closer to the "actual" and final numbers than is available by other means.

Hope this information helps Design Builders and Electrical Contractors to increase their profits!

And remember, we have a free demonstration on the first Friday of each month: FREE Demo, Friday June 5th at 12 EST Hope you will join us!

Thank you for your support! Stay well.