13 Ways PowerCalc Saves Time / Saves Money

PowerCalc(tm) saves time and money every day and every project. So, never open the NEC Handbook again + a lot more. Here goes:

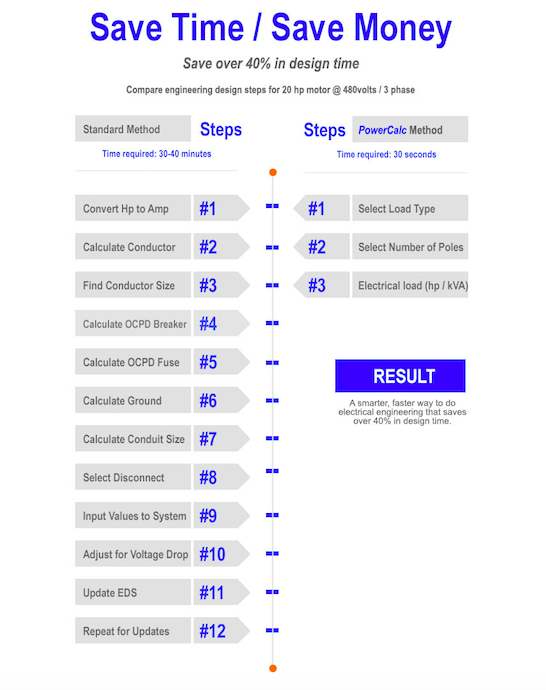

1. Only 3 inputs. PowerCalc's patented process only requires 3 inputs per circuit (load kVA, load type and # of poles).These 3 inputs generate over 300 NEC compliant outputs.As indicated in the chart above, simplifying these calculations saves at least 40% in design time.

2. Bottom - Up Design. PowerCalc designs from the bottom - up (circuit to the power grid). This allows for (i) actual engineering values to be used in the design and (ii) for PowerCalc's 7 million + equations to be bundled into a single integrated calculation. The result is an integrated and incomparably accurate design. Contrast this outcome with other softwares that require the project's end size to be estimated at project start including the voltage phase, panel frame, panel main and feeder. Can all these "estimates" be actively and accurately updated throughout the design process by multiple people? As virtually all electrical professionals have either heard or experienced, this "guestimated" process leads to frustrating and expensive errors.

3.Simultaneously Generated 1 Line Diagram.No more fuss at the end of the project on putting together your 1 Line Diagram...It is generated simultaneously throughout the design process. Your project is always in synch and can always be seen.1 Line Diagram

4. Unexpectedly Easy. Only 3 inputs per circuit...that's how easy it is to use PowerCalc. In fact, any conscientious staff member can input these values, and then the electrical professional can concentrate on the things which do need their focus...like connecting the panels and designing the power distribution.

5. NEC Compliant. PowerCalc's calculations are integrated with its proprietary database for compliance with the NEC. The electrical professional can override outputs to meet specific design requirements, but it is their choice. So, goodbye NEC look up tables.More on NEC

6. Instantaneous Changes. With a design completely integrated into one big calculation, any change anywhere in the design results in instantaneous updating upstream and downstream across the design. This is construction, so there are always changes. And with PowerCalc, the changes are instantaneous.

7. Demand Load / No over-design / No under-design. The NEC breaks the demand load into resistive, motor (inductive) and lighting loads. PowerCalc does the same thing all in compliance with the NEC. But other programs fail to track load types so cannot reduce their connected load sum by the relevant demand load as outlined in NEC Article 220 Branch Circuit, Feeder and Service Calculations. Developers, owners and clients get stuck with big bills for over-designed power distribution systems. Electrical equipment is expensive, and your clients will be far happier if you are saving them money rather than wasting their money by specifying unnecessary equipment. With PowerCalc, the electrical professional now has a way to easily avoid over-design concerns. Likewise, no possibility of under-design (not enough equipment specified) causing a safety concern.

8. Unmatched Accuracy. Simply, PowerCalc is not only incredibly accurate, but using software reduces human error.

9. Team Collaboration. PowerCalc is the only electrical engineering software in the cloud. This means that your team works and collaborates in real time any place, any time and on any device. It also means that version controls are in place as well as controls over who has access to project files. All the administrative headaches of the design process are now under control.

10. No Change Orders. PowerCalc is fully vetted - used for thousands of projects and billions in construction spend. Now that the design is accurate, the electrical professional is far less likely to have mistakes resulting in expensive change orders.

11. No Lawsuits. Likewise (same as #10), we know of no lawsuits based on design issues for users of PowerCalc.

12. No Comments. Again and same as #10 and #11, when you use PowerCalc, get used to not receiving comments from Building Departments on your submissions. And that saves a lot of time.

13. Automation. PowerCalc saves days of engineering man hours. Automation drives productivity across all businesses large or small. Changes, even small ones, over time snowball into massive gains in productivity. PowerCalc includes: automation of processes with databases, standards and updated procedures resulting in fewer errors, fewer building department comments and fewer issues with finished designs. And, just less time spent on design and repetitive calculations. AutoCalcs

Join us for a free demonstration and see PowerCalc in action for yourself this Friday, September 6th at noon EST. FREE Demo Sept. 6th

Look forward to working with you.